Guidelines for Safe Operation of Diesel Generator Sets

1、 Preparation before startup

Before starting up each time, it is necessary to check whether the cooling water or antifreeze in the diesel engine water tank meets the requirements. If it is missing, it should be filled up. Pull out the oil dipstick to check if there is a shortage of lubricating oil. If there is a shortage, add it to the specified "static full" scale line, and carefully inspect the relevant components for any potential faults. If any faults are found, they should be promptly eliminated before starting the machine.

2、 It is strictly prohibited to start the diesel engine with load

Before starting the diesel engine, it is important to note that the output air switch of the generator must be in the off state. After starting the diesel engine of a regular generator set, it needs to idle for 3-5 minutes (around 700 revolutions per minute). In winter, when the temperature is low, the idle time should be appropriately extended for a few minutes. After starting the diesel engine, the first thing to observe is whether the oil pressure is normal and whether there are any abnormal phenomena such as oil leakage or water leakage. (Under normal circumstances, the oil pressure must be above 0.2MPa.) If any abnormalities are found, the engine should be stopped immediately for maintenance. If there are no abnormal phenomena, increase the diesel engine speed to the rated speed of 1500 revolutions per minute. At this time, the generator displays a frequency of 50HZ and a voltage of 400V. Then, the output air switch can be closed and put into use. The generator set is not allowed to operate without load for a long time. If it is an automated generator set, it does not need to idle because it is usually equipped with a water heater to keep the diesel engine cylinder body at around 45 ℃ for a long time, and the diesel engine can be powered normally within 8-15 seconds after starting.

3、 Pay attention to observing the working status during operation

During the operation of the generator set, a dedicated person should be on duty to regularly observe a series of possible faults, especially the changes in important factors such as oil pressure, water temperature, oil temperature, voltage, and frequency. Additionally, it is important to have sufficient diesel fuel on hand. In the event of a fuel interruption during operation, it may cause a load stop and potentially result in damage to the generator excitation control system and related components.

4、 It is strictly prohibited to stop the engine with load. Before each stop, the load must be gradually cut off, then the output air switch of the generator set must be turned off, and finally the diesel engine must be slowed down to idle for about 3-5 minutes before stopping.

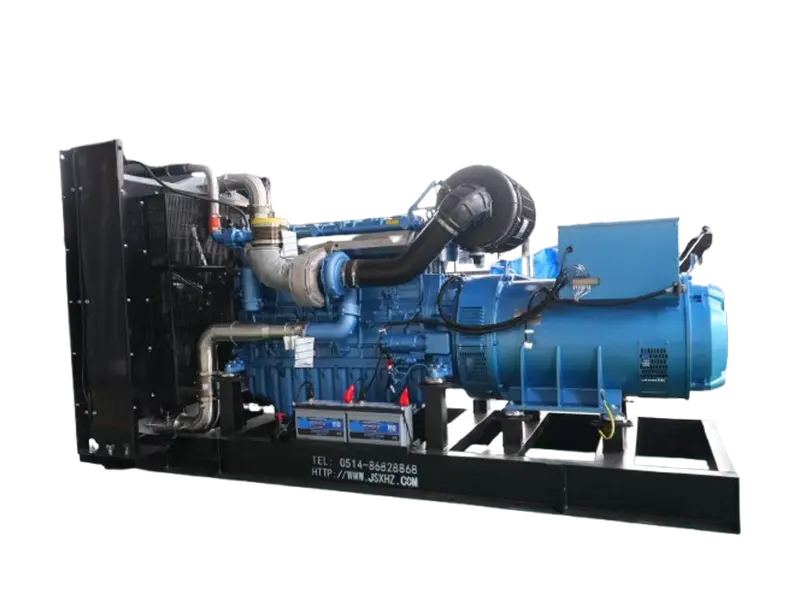

Diesel Generator Sets with Cummins Engines, XHZC Series

Diesel Generator Sets with Cummins Engines, XHZC Series Weichai Series

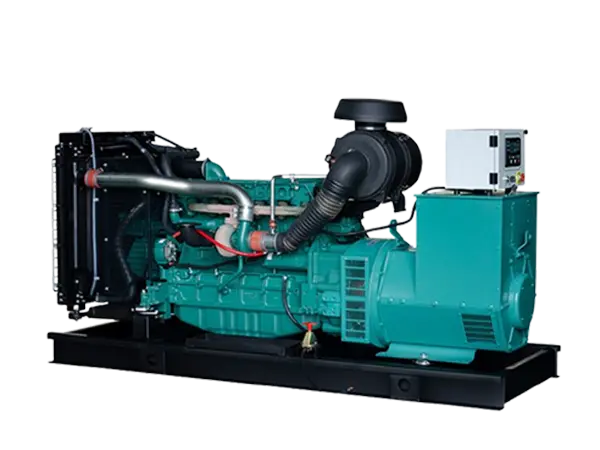

Weichai Series Diesel Generator Sets with WEICHAI Engines, XHZW Series

Diesel Generator Sets with WEICHAI Engines, XHZW Series Yuchai Series

Yuchai Series Diesel Generator Sets with SDEC(SHANGCHAI) Engines, XHZS Series

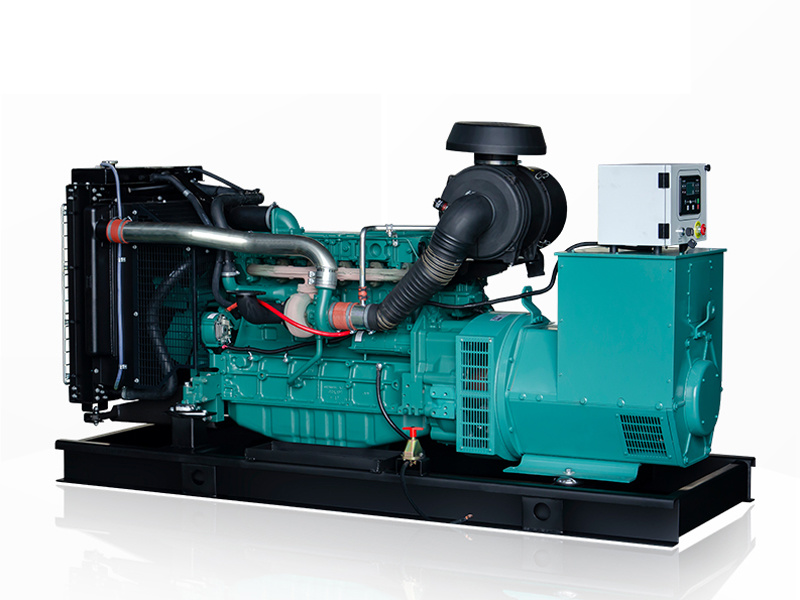

Diesel Generator Sets with SDEC(SHANGCHAI) Engines, XHZS Series Volvo Series

Volvo Series Diesel Generator Sets with VOLVO Engines, XHZV Series

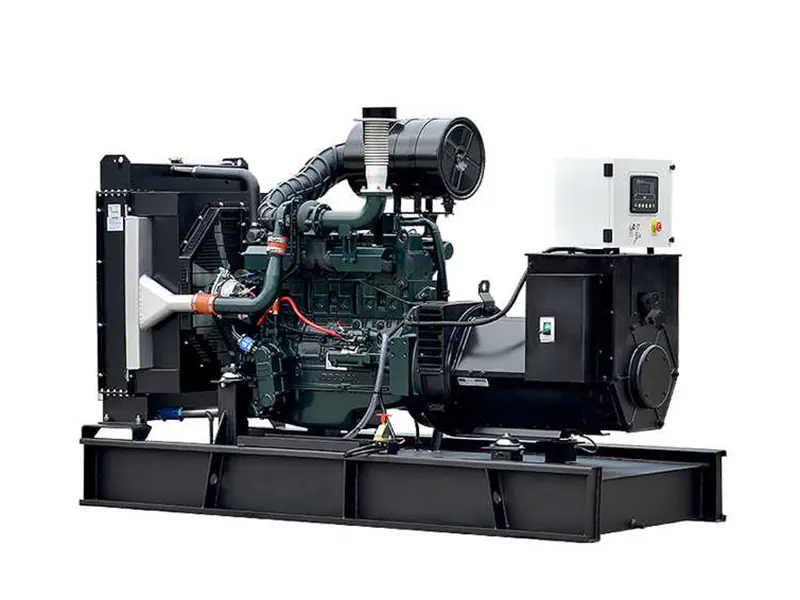

Diesel Generator Sets with VOLVO Engines, XHZV Series Diesel Generator Sets with Doosan Engines

Diesel Generator Sets with Doosan Engines Diesel Generator Sets with Perkins Engines, XHZP Series

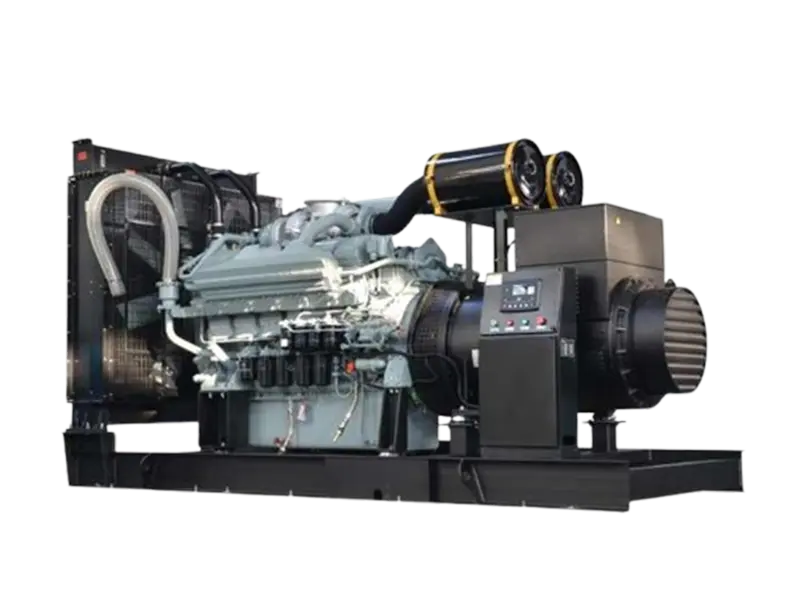

Diesel Generator Sets with Perkins Engines, XHZP Series Diesel Generator Sets with Mitsubishi Engines

Diesel Generator Sets with Mitsubishi Engines Silent Diesel Generators

Silent Diesel Generators Mobile Silent Diesel Generators

Mobile Silent Diesel Generators 20/40HQ-Standard Container Type Generators

20/40HQ-Standard Container Type Generators