-

Home

-

Products

-

Service

-

About Us

-

Solution

-

Videos

-

News

-

Contact Us

Leave Your Message

In a world where power outages can occur unexpectedly due to natural disasters, system failures, or other unforeseen circumstances, the significance of an Emergency Diesel Generator (EDG) becomes increasingly evident. These robust machines provide a reliable backup power source, ensuring that essential operations can continue without interruption. However, simply having an Emergency Diesel Generator on-site is not enough; understanding how to maintain and operate it effectively is vital for optimal performance when it’s needed the most.

This guide will delve into the top 10 tips for maximizing the reliability and functionality of your Emergency Diesel Generator. From routine maintenance practices to essential troubleshooting techniques, these insights will equip you with the knowledge necessary to ensure your generator remains in peak condition. As we navigate through these critical tips, you'll learn how to enhance your preparedness for any power-related emergencies and ultimately safeguard your home or business against the disruptions that accompany electrical failures.

Emergency diesel generators play a crucial role in ensuring reliable backup power during unexpected outages. According to industry reports, over 95% of businesses recognize the significance of having a backup power solution in place. These generators not only prevent downtime but also protect sensitive equipment from the potential damage caused by power fluctuations. As natural disasters and extreme weather events become increasingly common, the demand for effective backup power solutions remains high. Understanding how to utilize these generators effectively is essential for maintaining operational continuity.

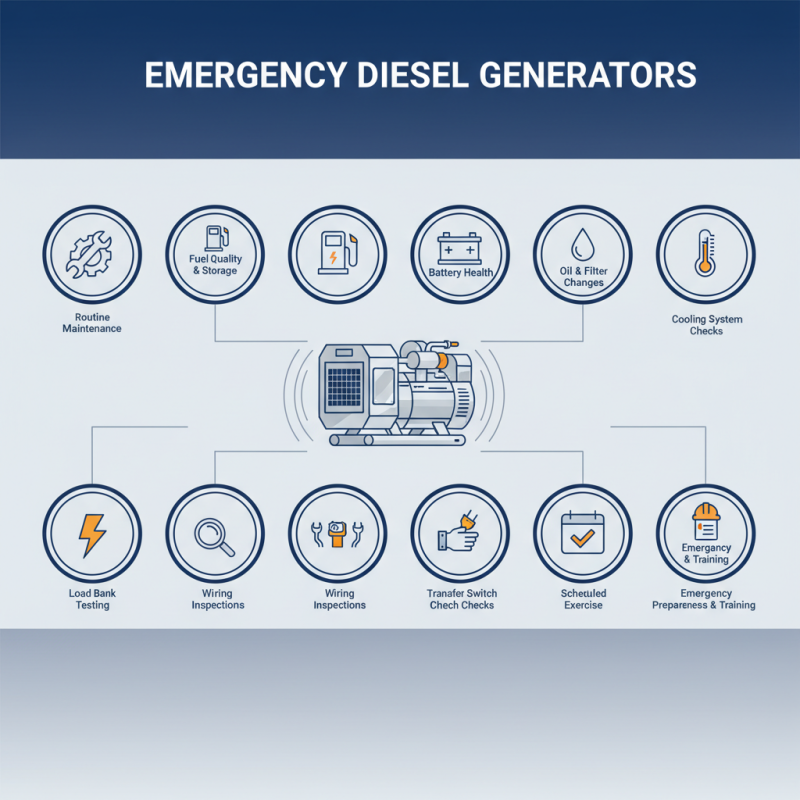

One key tip for maximizing the reliability of a diesel generator is regular maintenance. A study revealed that nearly 70% of generator failures can be attributed to a lack of proper upkeep. Routine inspections, oil changes, and fuel quality assessments can significantly extend the life of your generator. Additionally, investing in automatic transfer switches ensures a quick response during power loss, minimizing disruptions and providing peace of mind.

Another important consideration is fuel management. Statistics show that fuel quality directly impacts generator performance. Keeping fuel tanks adequately filled and free from contaminants helps maintain engine efficiency. Implementing a robust monitoring system that tracks fuel levels and quality can prevent unexpected outages. By adhering to these essential tips, businesses can ensure their backup power systems are reliable and ready to respond when it matters most.

When selecting the right diesel generator for your needs, several key factors should guide your decision-making process. First and foremost, consider the power requirements of the appliances and equipment you intend to run during an emergency. Estimating the total wattage will help you determine the generator's size and output capacity, ensuring that it can handle the load efficiently without straining. Additionally, evaluate whether a continuous power supply or a standby solution is more appropriate for your situation, as this will influence the generator's design and features.

Another important factor is the generator's run time and fuel efficiency. Look for models that offer extended run times on a single tank of diesel, as this not only reduces the frequency of refueling but also enhances reliability during prolonged outages. Noise levels can also be a consideration, especially in urban or residential areas; quieter generators can provide functionality without disturbing your neighbors.

Lastly, assess the generator's portability if you anticipate needing it for various locations, and ensure that maintenance requirements are manageable and accessible to keep the equipment in optimal condition. By carefully weighing these aspects, you can select a diesel generator that meets your specific backup power needs reliably and efficiently.

Routine maintenance is essential for ensuring the reliability of diesel generators, especially when they are needed as backup power sources during emergencies. According to industry statistics, approximately 70% of generator failures can be attributed to a lack of proper maintenance. Regularly scheduled inspections and maintenance practices help prevent unexpected breakdowns and ensure smooth operation when power outages occur.

One key maintenance tip is to perform regular oil and filter changes. According to the Electric Power Research Institute, changing the oil at intervals of 150 to 300 hours of operation can significantly extend the life of your generator. Additionally, inspecting fuel systems for contamination and ensuring proper fuel filtration are crucial steps to maintain optimal performance. It’s also advisable to run the generator under load for a short duration each month to keep the engine components lubricated and avoid the potential for corrosion.

Another important practice is to check the battery and electrical connections. The National Fire Protection Association recommends conducting routine tests to assess the battery’s capacity and integrity. Ensuring that connections are clean and free of corrosion can lead to better performance and reduce the risk of failure during crucial moments. By adopting these maintenance practices, you can enhance the reliability of your diesel generator and secure peace of mind when backup power is needed most.

Proper fuel storage and management are crucial for ensuring the reliability of diesel generators during emergencies. One essential practice is to store fuel in secure, well-ventilated containers that are suitable for diesel. This helps prevent contamination and degradation of the fuel, which can occur when exposed to air or moisture. Additionally, it is important to keep storage tanks away from direct sunlight and heat sources to maintain the fuel's stability and prevent evaporation losses.

Regularly checking and maintaining fuel quality is equally important. This can be done by implementing a routine inspection schedule that includes testing for water, sediment, and microbial growth in the fuel. Using fuel biocides and water separators can minimize the risks associated with microbial contamination, leading to more efficient generator operation. Furthermore, always keeping records of fuel storage conditions and maintenance activities is vital to ensure compliance and optimize the performance of your diesel generator during critical times.

When operating emergency diesel generators, ensuring safety is paramount.

Before starting the generator, it is essential to conduct a thorough inspection of the unit and its surroundings. This includes checking for flammable materials nearby and ensuring proper ventilation to avoid hazardous fumes from accumulating. Make sure to wear appropriate personal protective equipment, such as gloves and goggles, to safeguard against any potential hazards.

Once the generator is operational, continuous monitoring is crucial. Operators should remain alert to any signs of malfunction, such as unusual noises or vibrations, which could indicate mechanical failure. It's also important to maintain a safe distance from the generator while it is running, as the engine components can become extremely hot during operation. Additionally, adhering to proper shutdown procedures when the generator is no longer needed can help prevent accidents and extend the lifespan of the equipment. Following these safety precautions not only ensures efficient power backup but also protects the well-being of all personnel involved.