-

Home

-

Products

-

Service

-

About Us

-

Solution

-

Videos

-

News

-

Contact Us

Leave Your Message

When it comes to ensuring reliable power supply in various industrial applications, selecting the right Industrial Diesel Generator (IDG) is paramount. With a multitude of options available on the market, understanding key metrics and performance insights becomes essential for achieving optimal efficiency. Factors such as power output, fuel consumption, maintenance requirements, and environmental impact should all be considered in the selection process. Additionally, evaluating the specific needs of your operations, including load demands and operational flexibility, will play a crucial role in making an informed decision. This guide aims to provide a comprehensive overview of the most critical aspects to consider when choosing an Industrial Diesel Generator, helping you navigate the complexities and ultimately enhance the performance and sustainability of your industrial operations.

When selecting the right industrial diesel generator, various factors must be considered to ensure optimal efficiency and performance.

Firstly, the power rating is crucial, as it determines the generator's suitability for specific applications. Depending on the operational needs, options range from below 75 kVA for lighter applications to above 750 kVA for heavy industrial uses. Understanding the power requirements of operations can significantly influence the overall efficiency and reliability of the power supply.

Another important consideration is the fuel type. Diesel generators typically offer advantages such as greater fuel efficiency and longer operational life compared to gas-powered alternatives. However, factors such as fuel availability, cost fluctuations, and environmental regulations should also be evaluated. Choosing the right fuel type can enhance the generator's performance while minimizing operational challenges.

Ultimately, meticulous consideration of power ratings and fuel types ensures that businesses invest in a diesel generator that aligns with their productivity and sustainability goals.

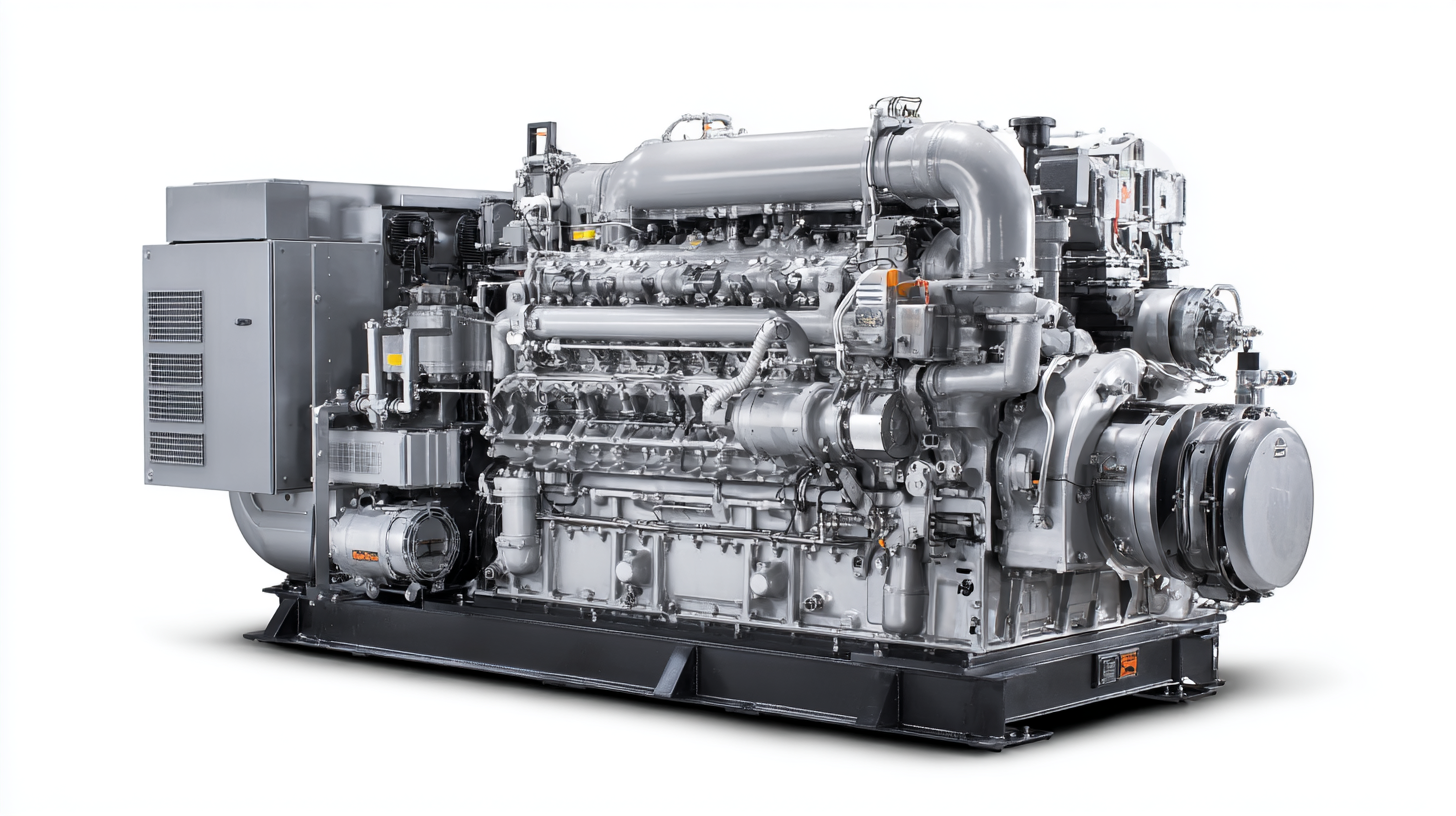

When selecting an industrial diesel generator, understanding key performance metrics is crucial for assessing its efficiency. One of the primary metrics to consider is the generator’s fuel consumption rate, typically measured in liters or gallons per hour at full load. A generator with a lower fuel consumption rate signifies higher efficiency, translating to reduced operational costs over time. Additionally, evaluating the generator's load capacity—expressed in kilowatts (kW)—is essential. This ensures that the chosen generator can meet the power requirements of your operations without being overworked, which can lead to premature wear and increased maintenance costs.

Another important metric is the generator's total harmonic distortion (THD), which indicates the level of distortion in the power output. Lower THD values suggest cleaner power, reducing the risk of equipment damage and extending the lifespan of sensitive electronics. Furthermore, operational factors such as the generator’s runtime between maintenance and its overall reliability during operation should also be scrutinized. A generator that requires less frequent servicing and operates consistently under various load conditions can significantly enhance productivity and minimize downtime. These insights are vital for making an informed choice that aligns with your industrial needs.

When selecting the right industrial diesel generator, understanding fuel consumption ratings is crucial for achieving optimal efficiency. Diesel generators often vary significantly in their fuel consumption based on factors such as load size, operating conditions, and engine efficiency. Fuel consumption ratings are typically expressed in gallons or liters per hour at a specified load percentage. This metric provides insight into how much fuel the generator will consume under different operational scenarios, allowing businesses to project fuel expenses accurately.

Moreover, evaluating the generator's fuel consumption ratings in relation to its power output helps in determining its operational cost-effectiveness. A generator that consumes less fuel while providing adequate power can lead to significant savings in the long run. Additionally, understanding the impact of fuel type and quality on consumption is essential. High-quality diesel fuels often enhance performance and efficiency, reducing the likelihood of excessive consumption due to engine wear or inefficiencies. By carefully analyzing these factors, businesses can select a diesel generator that aligns with their energy demands while maximizing fuel efficiency.

| Generator Model | Rated Power (kW) | Fuel Type | Fuel Consumption (L/h) | Efficiency (%) | Run Time (h) |

|---|---|---|---|---|---|

| Model A | 150 | Diesel | 15 | 92 | 10 |

| Model B | 200 | Diesel | 20 | 90 | 12 |

| Model C | 300 | Diesel | 30 | 88 | 11 |

| Model D | 400 | Diesel | 35 | 85 | 10 |

When selecting the right industrial diesel generator, evaluating durability and maintenance requirements is paramount. A generator's construction materials and design can significantly impact its lifespan and reliability. Opting for models built from high-quality, rust-resistant materials ensures they can withstand harsh environments and operate efficiently over extended periods. Additionally, reviewing the generator's operational history and user reviews can provide insights into its long-term performance and potential issues.

Regular maintenance is essential for the longevity of a diesel generator. Understanding the maintenance intervals and requirements outlined by the manufacturer can aid in keeping the unit running smoothly. This includes routine checks on the engine, fuel system, and electrical components. Generators that offer easy access to critical components will facilitate quicker inspections and repairs, reducing downtime. Moreover, considering models with advanced diagnostic features can help identify issues before they become significant problems, further enhancing performance and reliability.

When selecting an industrial diesel generator, determining the right size and capacity is crucial to avoid inefficiencies and ensure reliable power supply. The first step in this process is to assess the total energy requirements of the facility. This includes evaluating the power demands of all equipment and systems that will be supported by the generator. It is essential to consider peak load conditions, which can be significantly higher than average consumption levels, as well as any future expansion plans that may require additional power capacity.

In addition to the total kilowatt (kW) needs, factor in the generator's power factor, which indicates how efficiently the electrical power is being converted into usable power. A generator rated for a lower power factor may not deliver adequate energy to all connected loads, leading to potential interruptions and costly downtime. By accurately calculating both the standard and peak load requirements and considering the power factor, businesses can select an industrial diesel generator that not only meets current needs but is also flexible enough to accommodate future growth, ultimately optimizing efficiency and performance.