-

Home

-

Products

-

Service

-

About Us

-

Solution

-

Videos

-

News

-

Contact Us

Leave Your Message

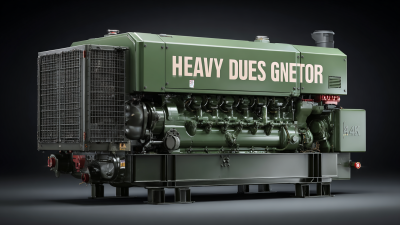

In today's rapidly evolving energy landscape, the demand for reliable power solutions continues to grow, particularly in sectors where operational consistency is critical. Heavy duty diesel generators have emerged as a preferred choice for businesses that require robust and uninterrupted power supply. According to John Smith, a prominent expert in the diesel generator industry, "Heavy Duty Diesel Generators stand as the backbone of operational reliability, especially in industries where downtime can lead to significant financial losses."

As we explore the top 10 heavy duty diesel generators suited for a variety of applications, it becomes clear that these machines are not just about high output and durability; they also embody advancements in technology, efficiency, and user-friendliness. These generators are designed to withstand extreme conditions and provide dependable performance, ensuring that businesses can maintain operations effectively, regardless of the power challenges they face.

Understanding the features and specifications of heavy duty diesel generators is essential for making informed decisions. This guide will delve into the most reliable options on the market, each tailored to meet diverse power needs, thus enabling organizations to thrive in an increasingly competitive environment.

When choosing a heavy-duty diesel generator, several key features should be considered to ensure reliability and efficiency. First and foremost, look for a generator with a robust engine that can handle demanding workloads. A generator’s output capacity, measured in kilowatts, is critical; selecting one that meets or exceeds your power needs is essential for preventing outages during critical operations. Fuel efficiency also plays a vital role—opt for models with advanced fuel management systems that optimize consumption while reducing operational costs.

Another important aspect is the generator’s noise level. Selecting a unit designed with soundproofing technology can significantly minimize disturbances, particularly in residential areas or quiet work environments. Additionally, consider the ease of maintenance and access to parts for servicing; generators that are built with user-friendly features can save time and money in the long run.

Tips: Regular maintenance is crucial for the longevity of your generator. Schedule routine checks every few months, focusing on essential components such as the oil level, fuel filters, and battery condition. Furthermore, ensuring that the generator is stored in a clean, dry location helps prevent unnecessary wear and tear, allowing dependable performance when you need it most.

When selecting a heavy-duty diesel generator to meet your power needs, understanding power output ratings such as kilowatts (kW) and kilovolt-amperes (kVA) is essential. While both measurements indicate the generator’s capacity, they serve different purposes. kW refers to the actual power used by appliances and equipment, making it critical when assessing how much power your tools or systems require for operation. For instance, if you have devices with high energy consumption, you'll want to ensure the generator's kW rating can handle their cumulative load.

On the other hand, kVA is a measure of the total power that the generator can deliver, factoring in both real power (kW) and reactive power. Reactive power is used in inductive loads such as motors and transformers, which affect the generator’s overall efficiency. The relationship between kVA and kW is influenced by the power factor, which typically ranges from 0.8 to 1 for generators. When evaluating your generator options, consider your power factor to accurately determine what size generator you need; this calculation will ensure that you have sufficient capacity to meet both your current and future power demands effectively.

This chart illustrates the power output ratings of the top 10 heavy-duty diesel generators, comparing their kW and kVA values to aid in understanding your power needs.

When it comes to heavy-duty diesel generators, fuel efficiency is a crucial factor for both sustainability and cost-effectiveness. Recent industry reports indicate that modern diesel generators can achieve fuel consumption rates as low as 0.2 gallons per kilowatt-hour (g/kWh). This efficiency is not only beneficial for reducing operational expenses but also plays a significant role in minimizing the environmental impact associated with fossil fuel consumption. The ability of generators to run efficiently under varying loads further enhances their reliability, making them ideal for critical applications in construction, telecommunications, and emergency backup power.

Moreover, advances in diesel technology have led to improved fuel injection systems and engine designs that optimize combustion processes. According to data from the Clean Diesel Technology Program, recent developments in fuel injection can improve fuel efficiency by up to 15%, which translates to substantial savings over the generator's life cycle. Additionally, manufacturers are increasingly focusing on designing generators that comply with stringent emissions regulations without sacrificing performance. This shift not only adheres to environmental standards but also extends the operational life of the equipment, ensuring that they remain a dependable source of power for various industrial applications.

When it comes to heavy-duty diesel generators, ensuring reliability and durability is paramount, especially in industries where power needs are critical. To achieve these reliability standards, manufacturers subject generators to rigorous testing protocols that evaluate their performance under extreme conditions. According to industry reports, including findings from the American National Standards Institute (ANSI), generators must undergo load testing, vibration testing, and thermal cycling assessments to ensure they can handle the stresses of continuous use without failure. Each generator is typically rated based on its capacity to withstand outdoor environments, fluctuating temperatures, and high operational demands.

Furthermore, the durability of heavy-duty diesel generators is often quantified using the Mean Time Between Failures (MTBF) metric, which serves as an indicator of reliability. According to the Electric Power Research Institute (EPRI), top-performing generators can achieve an MTBF of over 20,000 hours under optimal conditions. Additionally, advanced materials and engineering practices, such as the use of corrosion-resistant components and shock mounts, play a pivotal role in enhancing the longevity and resilience of these machines. By adhering to these stringent testing guidelines and leveraging advanced technology, manufacturers can ensure that their heavy-duty diesel generators provide reliable power for critical applications, minimizing downtime and operational disruptions.

| Model | Power Output (kW) | Engine Type | Fuel Capacity (liters) | Run Time (hours) | Noise Level (dB) | Weight (kg) |

|---|---|---|---|---|---|---|

| Model A | 50 | 4-Stroke | 120 | 10 | 75 | 350 |

| Model B | 100 | 6-Cylinder | 150 | 12 | 78 | 450 |

| Model C | 75 | Inline-4 | 130 | 9 | 80 | 400 |

| Model D | 125 | V8 | 200 | 15 | 85 | 600 |

| Model E | 150 | V12 | 250 | 20 | 90 | 750 |

| Model F | 200 | Turbocharged | 300 | 25 | 92 | 800 |

| Model G | 250 | Diesel | 350 | 30 | 95 | 900 |

| Model H | 300 | Heavy Duty | 400 | 35 | 96 | 1000 |

| Model I | 350 | Twin Turbo | 500 | 40 | 98 | 1100 |

| Model J | 400 | Heavy Duty | 600 | 45 | 100 | 1200 |

The demand for diesel generators has seen a notable increase in various sectors, driven by the need for reliable power solutions amidst rising energy costs and a growing emphasis on sustainability. Industries such as construction, healthcare, and agriculture heavily depend on these generators to ensure uninterrupted operations, especially in remote locations where grid power may be unreliable. As a result, manufacturers are ramping up production to meet this surge in demand, but supply chain challenges still pose a significant barrier to accessing these vital power sources.

As the market evolves, it is essential for buyers to stay informed about the latest trends and innovations in heavy-duty diesel generators. One effective tip for potential purchasers is to assess their power requirements meticulously, ensuring they select a generator with adequate capacity to handle peak loads. Additionally, investing in advanced monitoring and maintenance systems can enhance reliability and longevity, ultimately leading to cost savings over time.

On the supply side, understanding the lead times for delivery is crucial, as some regions may experience longer waiting periods due to logistical delays. Prospective buyers should consider establishing relationships with local distributors to gain insights into availability and to ensure they are among the first to access new units. By staying informed and making strategic choices, businesses can navigate the complexities of the diesel generator market effectively.