-

Home

-

Products

-

Service

-

About Us

-

Solution

-

Videos

-

News

-

Contact Us

Leave Your Message

In industries that require reliable power solutions, the Heavy Duty Diesel Generator plays a crucial role. Dr. John Smith, an expert in energy systems, emphasizes, "These generators are the backbone of many operations." They provide continuous energy, particularly in remote locations or during power outages.

Heavy Duty Diesel Generators are built to withstand harsh environments. They deliver substantial power for long periods. However, they require regular maintenance to ensure efficiency. Without proper care, performance can drop significantly. This is a reality many operators face.

Their functionality hinges on robust design and engineering. These generators convert fuel into electrical energy through a complex process. While they are reliable, fuel costs and emissions continue to be contentious issues. Balancing power needs with sustainability remains a challenge in the industry. Investing in a Heavy Duty Diesel Generator is not just about upfront costs; it’s about long-term operational goals.

A heavy duty diesel generator is a powerful machine designed for demanding environments. These generators are commonly used in construction sites, mines, and large industrial operations. They provide a reliable power source when the grid is down or unavailable. The diesel engine powers the generator, allowing it to produce electricity efficiently and effectively.

Heavy duty diesel generators typically have a high output capacity. They can range from 500 kW to several megawatts. According to industry reports, the global diesel generator market is projected to reach $25 billion by 2024. This growth indicates an increasing reliance on diesel power solutions. Besides, heavy duty generators often feature robust construction to withstand harsh conditions.

These machines have unique operational characteristics. They run on diesel fuel, which is more efficient than gasoline. However, high emissions can be a concern. Regulatory measures are tightening, and companies must consider sustainability. In a world focused on greener technologies, heavy duty diesel generators face challenges. Balancing efficiency and compliance is critical for future use.

Heavy duty diesel generators are essential in various industries. They provide reliable energy, especially in remote areas. The key components of these generators play a significant role in their effectiveness and durability.

One major component is the engine. These engines are designed for high performance and longevity. They often come with advanced cooling systems, which prevent overheating. According to industry reports, heavy-duty diesel engines can last over 10,000 hours with proper maintenance. Another vital part is the alternator. This converts mechanical energy into electrical energy. Its efficiency directly impacts power output. An efficient alternator can improve fuel economy significantly.

Fuel systems are equally important. They need to supply diesel effectively to the engine. High-quality filters are essential to prevent contaminants. Poor filtration can lead to engine failures, resulting in costly downtime. Data shows that improper filtration can decrease engine life by up to 30%. Other components include the control panel and exhaust systems. They help monitor performance and manage emissions. These systems must comply with environmental regulations, which can be a challenging aspect of generator design. Ensuring all components work harmoniously is crucial for optimal generator performance.

A heavy-duty diesel generator is a robust power source. It is designed to handle demanding tasks. These generators are often employed in industrial settings. They are reliable even under strenuous conditions.

When a heavy-duty diesel generator operates, the process begins with fuel injection. The diesel fuel is mixed with air in the combustion chamber. This mixture is then compressed, leading to ignition. The energy produced turns the crankshaft. This mechanical movement generates electricity. The generator can provide power for various applications, from construction sites to remote areas.

However, maintenance can be challenging. Regular checks are essential to ensure optimal performance. Neglecting them may lead to significant issues. Fuel quality matters too. Impurities can affect engine efficiency. Sometimes, operational costs can exceed budgets. Keeping track of these factors is crucial for sustainable use.

Heavy duty diesel generators are versatile machines. They provide reliable power in various settings. Often, they are used in construction sites. These generators operate efficiently under demanding conditions. They help keep projects on schedule, even in remote areas.

In addition to construction, heavy duty diesel generators serve hospitals. They supply backup power during outages. Hospitals require uninterrupted electricity for life-saving equipment. These generators also support events like concerts and festivals. They ensure that sound systems and lighting remain functional.

Even in agriculture, these generators play a role. Farmers rely on them for irrigation systems. However, not all generators are the same. Some may not perform well under certain weather conditions. It’s essential to consider specific needs for each application.

| Dimension | Value | Unit | Application Area |

|---|---|---|---|

| Power Output | 100 | kW | Construction Sites |

| Engine Type | V8 Diesel | - | Industrial Applications |

| Fuel Capacity | 200 | Liters | Mining Operations |

| Runtime at Full Load | 10 | Hours | Emergency Backup |

| Weight | 1500 | kg | Power Plants |

| Noise Level | 75 | dB | Urban Areas |

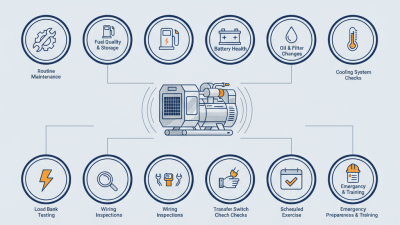

Heavy-duty diesel generators require regular maintenance for optimal performance. According to industry reports, neglecting maintenance can lead to decreased efficiency and higher operational costs. Diesel engines are complex systems. Each component must be checked regularly. This includes oil levels, cooling systems, and fuel filters. Regular maintenance can extend the lifespan by up to 50%.

Routine inspections are essential. Engine oil needs changing every 250 hours or as per manufacturer guidelines. Fuel quality also matters. Contaminated fuel can lead to poor performance. As much as 90% of engine failures are linked to fuel system issues. Operators should monitor the quality of fuel regularly.

A common mistake is overlooking small issues. A minor leak can turn into a significant problem if not addressed immediately. Generators should be run under load at least once a month. This helps identify potential issues early. Training personnel on best practices is vital. Keeping proper records of maintenance also ensures accountability and can highlight recurring problems. Regular maintenance is not just a task; it's a commitment to efficiency and reliability.