-

Home

-

Products

-

Service

-

About Us

-

Solution

-

Videos

-

News

-

Contact Us

Leave Your Message

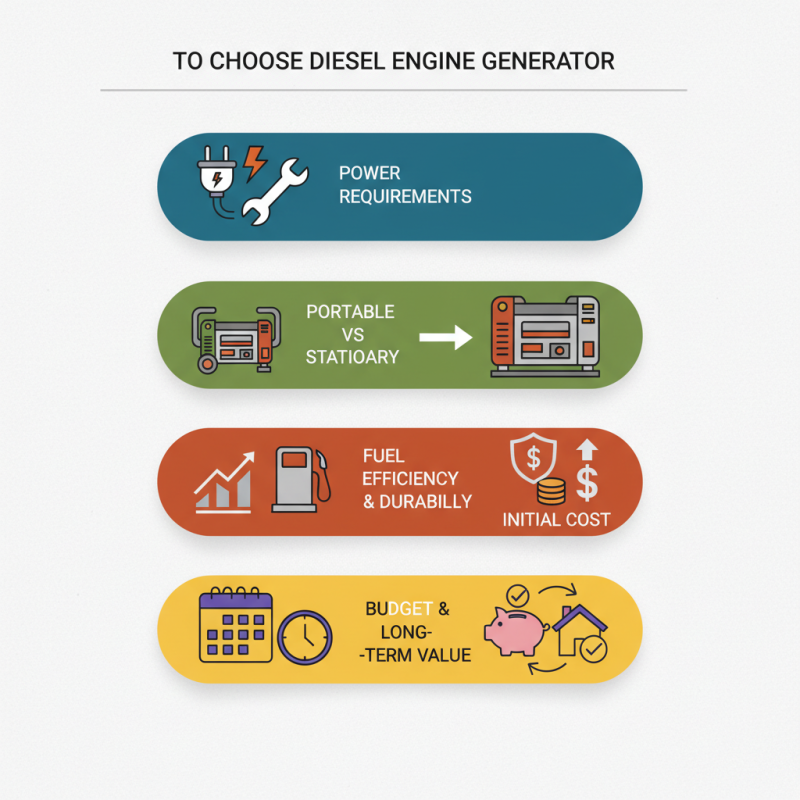

Choosing the right Diesel Engine Generator is crucial for ensuring reliable power supply. With various options available, the selection process can feel overwhelming. Each generator has unique features, making it essential to understand your specific needs before making a choice.

Consider the power requirements based on your appliances or tools. Think about whether you need a portable or stationary generator. A Diesel Engine Generator is well-known for fuel efficiency and durability. However, it may come with higher initial costs.

Evaluate how often you'll use the generator. If it's for regular use, investing in a quality Diesel Engine Generator is wise. For occasional use, a less expensive model might suffice. Reflect on your budget and the overall value of the generator over time. The right choice can provide peace of mind during power outages and emergencies.

Understanding your power requirements is crucial when choosing a diesel engine generator. Start by identifying the devices you need to power.

Make a list of essential equipment. Consider the wattage each device consumes. For example, a refrigerator might need around 600 watts. A small air conditioner could require up to 2000 watts. Add these numbers to find your total power requirement.

It's not enough to know just the running wattage. You also need to account for starting wattage. Appliances with motors, like pumps or compressors, draw more power at startup. This value can be two to three times higher. It's important to consider this when calculating your needs. You don't want to end up with a generator that's underpowered. This mistake could lead to frustrating downtime.

Think about your usage patterns. Will the generator run continuously, or only during outages? Continuous use might require a larger or more durable unit. Reflect on fuel efficiency too. A fuel-efficient generator can save you money over time. Skipping this thought could lead to unexpected costs. This choice affects both your budget and environmental impact.

When evaluating different types of diesel engine generators, it’s vital to consider their key features and applications. Diesel generators are available in portable and stationary models. Portable generators are ideal for temporary uses, such as construction sites or outdoor events. Stationary units are preferred for backup power in commercial settings. About 30% of businesses utilize stationary generators for this purpose, highlighting their importance in maintaining operations during outages.

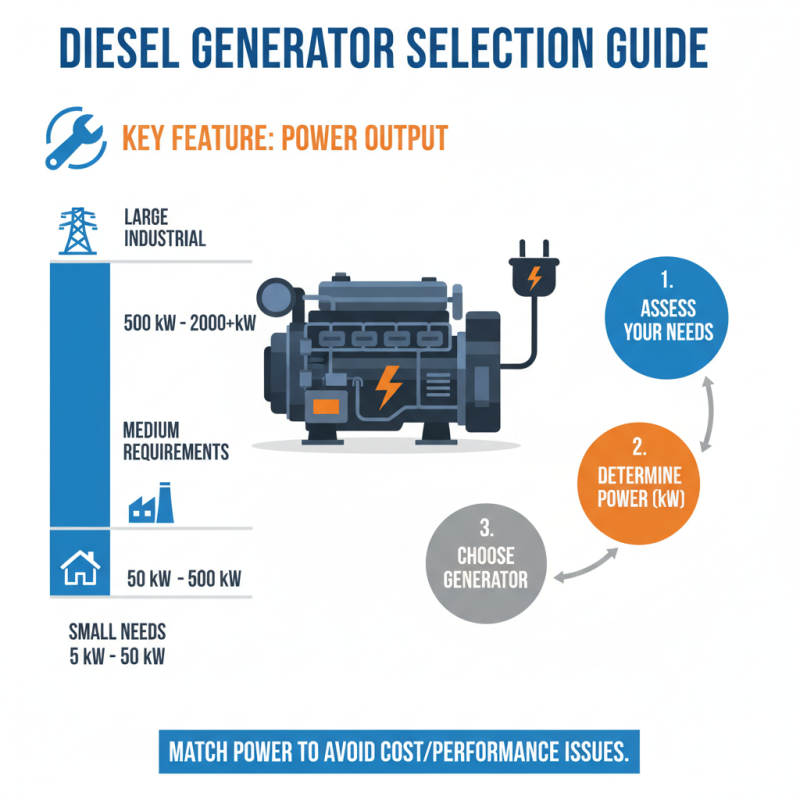

Understanding the power output is crucial. Diesel generators can range from 5 kW to over 2000 kW, catering to different needs. The right choice often depends on the load requirements of the equipment being powered. Data shows that generators operating at 70-80% capacity are most efficient, minimizing fuel consumption. Fuel efficiency is particularly critical since it can significantly affect operational costs over time.

Think about the environment too. Many modern diesel engines comply with stricter emissions standards. However, there may be differences depending on the unit. Ensuring you select a generator with appropriate emissions ratings is important. Some users find it challenging to balance power needs with environmental concerns. It’s wise to reflect on these aspects before making a purchase.

When selecting a diesel engine generator, key features are crucial. Power output is paramount. Assess your power requirements accurately. Most generators range from 5 kW to over 2,000 kW. Understanding your needs helps avoid overspending or underperformance.

Fuel efficiency is another important factor. Diesel generators are known for their longevity and efficiency. According to industry reports, they often provide better fuel economy than gasoline generators. Look for models that offer an optimal balance between power output and fuel consumption.

Tips: Check the generator's runtime on a full tank. Ensure you have access to diesel fuel. Sound levels can also vary. If noise is a concern, consider a model with sound attenuation features. Don’t overlook maintenance requirements. Some units may need more frequent servicing than others.

Evaluate the generator's build quality. Industrial-grade models usually last longer. Look for corrosion-resistant materials, especially if used in harsh environments. Remember, investing in a reliable unit can save money and stress over time.

When considering a diesel engine generator, fuel efficiency is a key factor. You want a model that offers optimal performance while minimizing running costs. Look for information on consumption rates and load capacities. Some generators perform better under specific loads. This plays a crucial role in your fuel expenses.

Maintenance needs are another essential aspect. Diesel generators require regular checks to ensure reliability. Simple tasks, like oil changes and filter replacements, help the generator run smoothly. However, not everyone enjoys the upkeep. Some might overlook small issues, leading to bigger problems later on. Neglect can lead to costly repairs down the line.

You might wish to think about the frequency of use. Will it serve as a backup source, or for daily tasks? Heavy use demands more maintenance. Also, consider where you will store the generator. Outdoor storage can expose it to the elements, affecting both efficiency and longevity. Reflecting on these aspects can lead to a more informed decision.

When determining your budget for a diesel engine generator, start by considering your power needs. Calculate the total wattage required for all devices and appliances. It is essential to estimate not just the continuous load, but also any peak or startup loads. This step ensures your generator has enough capacity to handle all demands without straining.

Next, think about long-term investment returns. A higher upfront cost may lead to better efficiency and durability. Look for generators with lower fuel consumption rates, as they can save money over time. Analyze maintenance requirements and potential repair costs. This helps paint a clearer picture of the overall expenses.

Don’t forget about installation costs. They can vary significantly based on your location and site conditions. The decision can be tricky. While a cheap option may seem appealing, it might not be cost-effective in the long run. Reflect on the expected lifespan and how often you will need to replace or upgrade. Consider how all these factors affect your financial plan.

This chart compares the costs of various diesel engine generators to help you determine the right choice based on your budget and expected return on investment.